The modern consumer is a demanding creature, always looking for something new and different. They are constantly spoiled by an extensive range of available products that make it nearly impossible to convince someone who’s already satisfied with their next purchase. The control over quality must be exceptional in order not only to keep up but also surpass this trendsetting culture.

With the advancement of technology, Artificial Intelligence (AI) has found its application in different fields such as education and healthcare. However, it is also used in various other fields like product quality control, robotics, etc. Recently, a lot of companies have been using artificial intelligence to help with their product quality control. The reason for this is that it has been proven that the use of AI can increase productivity by up to 30-40%. These numbers are very appealing to any company looking to cut costs while increasing production. However, there are some things you should know before you decide on whether or not your business will benefit from the AI process.

In this article, we will discuss how AI helps with product quality control.

How AI is working in Qualit Assurance

The most commonly used strategy for quality control is Anomaly detection. This has been an active research area over the past few decades, but there are still several unsolved challenges due to its unique and complex nature–unlike anything else in data science land! For instance: unknowingness (they remain unknown until they actually occur), heterogeneity (different anomalies demonstrate completely different abnormal characteristics), rareness (anomalies rarely occur data instances), diverse forms of anomalies (point anomaly, contextual anomaly, and group anomaly).

A few interesting papers published in recent years such as below.

The main idea here is to detect structural anomalies, and if there are any invokes the alert.

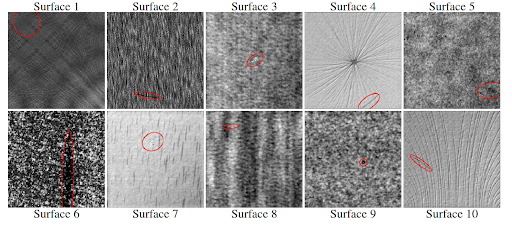

Here, for example, there are particular problems.

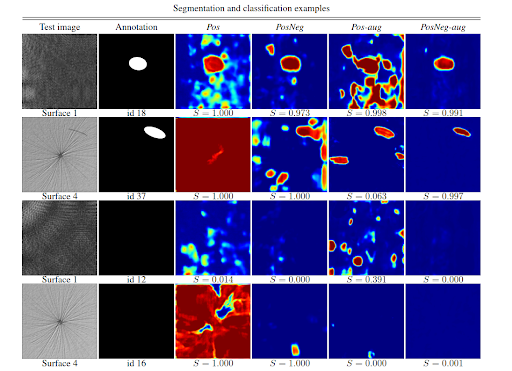

Once the network has trained to see when the surface has damage, it’ll show it like the following.

Quality control is an intricate process that cannot be fully realized without the proper attention. While humans are able to detect flaws in a few items, cameras would catch problems with each item passing through and also find any discrepancies too small for human eyesight. That’s why cameras placed above assembly lines would detect any anomalies on absolutely every single thing going by without fail. Plus, if something does happen, then there won’t be human error causing mistakes from happening since those types only have so many brain cells between them!

So the main takeaway is the following. First, the level of quality will go up dramatically. This is related to the speed of a check so as to pay attention to details.

If you would like help figuring out how artificial intelligence could work for your company or business, please contact us today. Our team of experts has decades worth of experience with various aspects of data analysis and we’d love to hear from you!

Materials used :

https://ieeexplore.ieee.org/document/8416441

https://www.sciencedirect.com/science/article/pii/S2212827119302409

https://arxiv.org/abs/1911.10608